What is bitumen

Bitumen has long been a familiar word for Iranians in our country.

In folk harvesting (bitumen is a black, stinky and sometimes unpleasant material that has two distinct properties: adhesion and sealing. It is derived from petroleum and is used in the preparation of asphalt or bitumen).

From the point of view of experts (a group of materials having a dark or dark (solid, semi-solid or viscose) adhesion with a natural or manufactured origin, the major constituents of which are high molecular weight hydrocarbons and soluble in carbon disulfide Are).

Bitumen Types: Because of the first importance of bitumen we define refinement bitumen.

A) bitumen:

The bitumens obtained directly from the distillation tower in the refinery vacuum or briefly aerated are called soft bit or pen grade and are named based on the degree to which the bitumen penetrates between them. For example, bitumen is 60/70 bitumen with a permeability of between 60 and 70 mm.

B) Blown Bitumen:

Bitumen is a solid that is usually solid at normal temperatures. Asphaltic materials are bituminous due to the blowing of polymer air and they are called “Rubberized Bitumen” bitumen. Bits of 90/15 and 100/40 are also in the bitumen family.

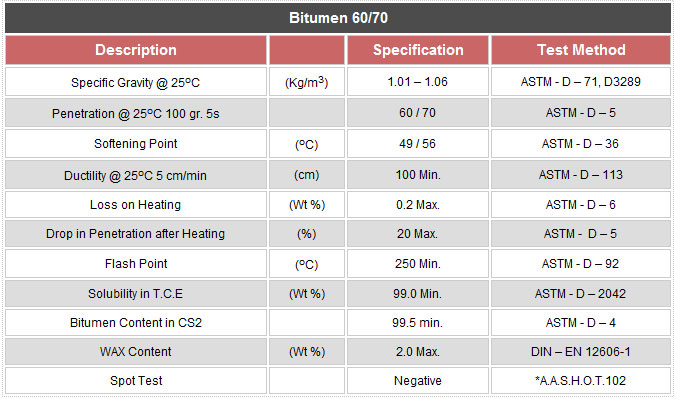

Bitumen 60/70

Bitumen 60/70

Bitumen is the bitumen obtained through the oxidation process on a vacuum baton (bitumen raw material obtained from the distillation residue in a vacuum oil refinery) so that the degree of permeability (a type of test) To determine the amount of bitumen stiffness it should be between 60 and 70.

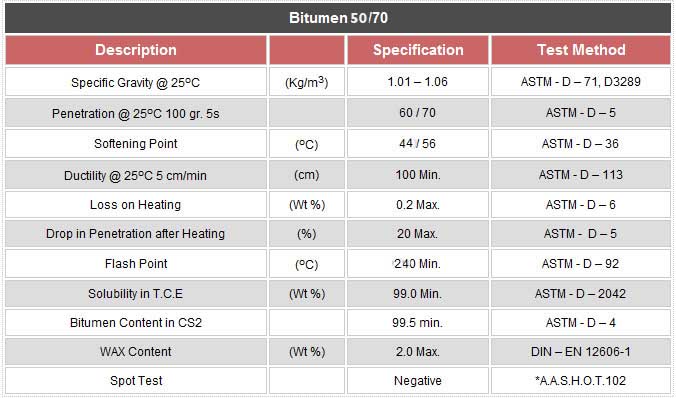

Penetration bitumen 50/70

Bitumen 50/70

Bitumen is a 70/50 bitumen that is obtained by the oxidation process on a vacuum bitumen (bitumen raw material obtained from the distillation residue in vacuum oil refineries) in bitumen units so that the degree of permeability is It should be between 50 and 70 degrees (an experiment to determine bitumen firmness)

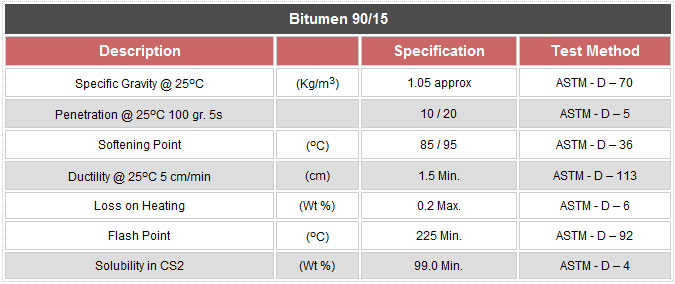

Penetrating bitumen 90/15

Bitumen 90/15

The mixture of the two raw materials, vacuum batons and vacuum solids, are aerated in our special pressurized bitumen reactors at temperatures between 0 ° C and 5 ° C to combine the hydrogen atoms in the asphalt molecules with oxygen and create hydrocarbon polymerization reactions to the hydrocarbon rocks. It is found to have less penetration and more softness than the original pure bitumen. This type of bitumen is its softness and permeability.

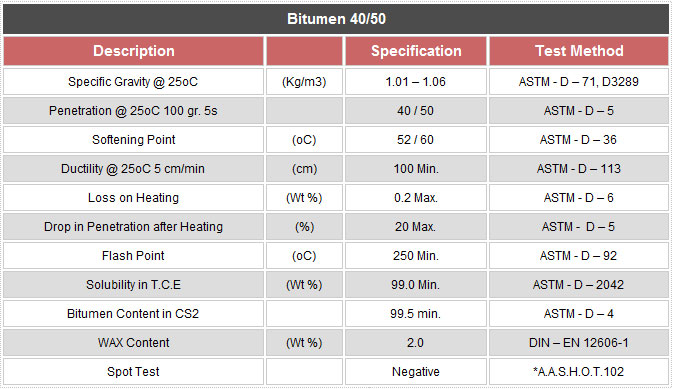

Bitumen 40/50

Bitumen 40/50

Bitumen is the bitumen obtained through the oxidation process on a vacuum baton (bitumen raw material obtained from the distillation residue in the vacuum of oil refineries) so that the degree of permeability (a test for Determine the amount of bitumen stiffness (40 to 50).

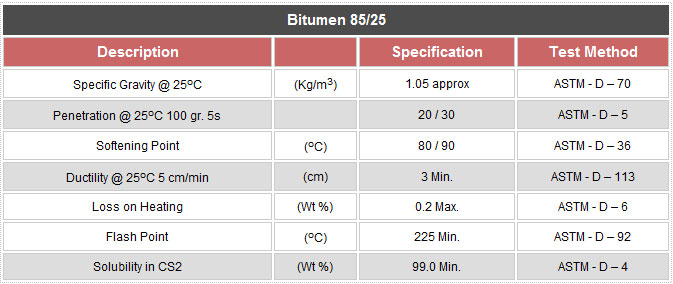

Bitumen 25/85

Bitumen 85/25

The mixture of the two raw materials, aqueous vacuum (VB) and vacuum soluble (VS), is aeration in specific pressurized bitumen reactors at temperatures between 200 ° C and 300 ° C to combine the hydrogen atoms in the asphalt molecules with oxygen and generate reactions. The polymerization of heavier hydrocarbons results in a lower permeability and a higher softening point than the pure primary bitumen. This type of bitumen is its softness 85 and permeability 25.

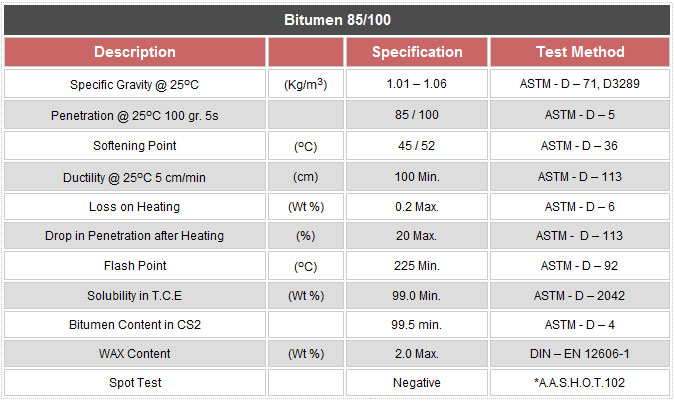

Bitumen 85/100

Bitumen 85/100

A bitumen is obtained in the bitumen by oxidation process on a vacuum batum (bitumen raw material obtained from the distillation residue in the oil refinery vacuum) so that the degree of permeability (a type of test) To determine the amount of bitumen firmness, it should be between 85 and 100.